- This event has passed.

Open Process Control (OPC) Server

Background & About the Course:

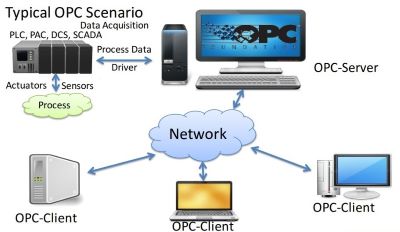

Open Process Control (OPC) is an industrial standard that facilitates seamless communication between devices and systems in industrial automation. By leveraging Microsoft’s COM and DCOM technology, OPC enables data exchange across multiple computers using a client/server architecture. This standardization allows applications to access data in a uniform format, regardless of the data source—whether it is a PLC, DCS, gauge, analyzer, or software application.

OPC simplifies connectivity, reduces integration time, and ensures interoperability across various systems and devices. Its ability to handle different connection types (serial, radio, Ethernet) and operate across diverse platforms makes it a cornerstone of modern industrial automation. This course is designed to provide participants with a comprehensive understanding of OPC, from configuration and integration to application development, fostering enhanced industrial connectivity and performance.

Course Objectives:

- Grasp the core concepts and architecture of OPC.

- Configure and implement OPC interfaces.

- Understand communication protocols in industrial automation.

- Set up and access OPC servers and clients.

- Integrate OPC with PLC, Human Machine Interface, and other industrial systems.

- Develop and manage OPC applications to improve operational efficiency.

Who Should Attend:

- Engineers, Supervisors, Technicians, and Operators in instrumentation, production, and operations.

- Professionals in communication, networking, IT, and reliability seeking better automation performance.

- Novice users aiming to build foundational knowledge in industrial data communication.

- Intermediate users looking to enhance skills in plant-office control and automation networks.

Course Content:

- Introduction to OPC

- Overview of OPC standards and architecture.

- Benefits and applications in industrial environments.

- OPC Configuration

- Setting up OPC servers and clients.

- Configuring communication pathways and troubleshooting common issues.

- Instrumentation Integration with OPC

- Connecting instruments and devices through OPC interfaces.

- Real-world examples and use cases.

- OPC Technology

- Exploring COM/DCOM technology in OPC.

- Understanding the role of OPC in distributed control systems.

- KeepServer and TOPSERVER

- Key features and practical use of KeepServer and TOPSERVER.

- Hands-on configuration and integration exercises.

- OPC Server and Client

- Understanding the interaction between OPC servers and clients.

- Managing data flow and performance optimization.

- Application Development

- Developing custom OPC applications.

- Enhancing connectivity and automation through tailored solutions.

- OPC Gateway and Connectivity

- Facilitating data exchange between different platforms and systems.

- Use of OPC gateways for cross-platform communication.

- OPC Integration with PLC and HMI

- Linking OPC to PLCs and HMIs for seamless data transfer.

- Practical case studies and demonstrations.

- Live Demonstration

- Real-time OPC setup, configuration, and troubleshooting.

- Q&A session to address specific participant questions.

About the Trainer:

Prof. Endra Joelianto, Ir., Ph.D., SMIEEE

Prof. Endra Joelianto, Ir., Ph.D., SMIEEE, is a leading expert in control engineering with research focusing on Hybrid Control Systems, Discrete Event Control Systems, Petri Nets, Robust PID Controllers, and Industrial Automation using PLC/DCS. He earned his Engineering Physics degree from ITB in 1990 and a PhD in Control Engineering from The Australian National University in 2001. Prof. Endra coordinates Intelligent Control and Automation at ITB and founded the PLC Research Group and Schneider-OMRON PLC Training Center, fostering collaboration with Schneider Electric, OMRON Corporation, and Invensys WONDERWARE.

He has led national retooling projects and participated in professional training on PLC, DCS, and calibration across Asia and Africa. As an instructor, he provides training in instrumentation and process control to universities and major companies in the petrochemical, oil and gas, and manufacturing sectors, including PERTAMINA, British Petroleum, and PT. Pupuk Kalimantan Timur. His contributions have significantly advanced industrial automation and education in Indonesia.