- This event has passed.

Drilling & Completion Well Integrity

Background & About the Course

Well Integrity refers to the organized application of technical, operational, and solution-oriented practices to minimize the risks associated with the life cycle of oil and gas wells and to create optimal operational conditions. Key influences include well conditions, environmental factors, and well-designed equipment. A comprehensive understanding of Well Integrity encompasses four main aspects: technical and design, operational, safety, and cost considerations.

During drilling operations, achieving targets related to trajectory, time, cost, and avoiding catastrophic losses from unforeseen drilling obstacles, such as uncontrolled kicks leading to blowouts, is crucial. In production, evaluations focus on well construction, artificial lift conditions, reservoir status, and production capabilities, alongside analyzing failures in operations.

Course Objectives:

- The fundamental concepts of Well Integrity.

- Well conduction and field development.

- Well barriers and technical well barriers.

- Operational aspects and performance related to well integrity during drilling, completion, and production operations.

Who Should Attend:

This training is recommended for:

- Drilling Engineers

- Drilling Superintendents

- Drilling Supervisors

- Rig Managers

- Service Company Drilling Personnel

- Workover Engineers

- Production Engineers

- Production Superintendents

- Production Supervisors

- Senior Operators

- HSE Supervisors

- Maintenance Supervisors

Course Outline

- Introduction to Well Integrity

- Well Integrity Management System and Risk Management

- Overview of Well Integrity Management Systems

- Risk Assessment Techniques

- Well Construction Evaluation and Development

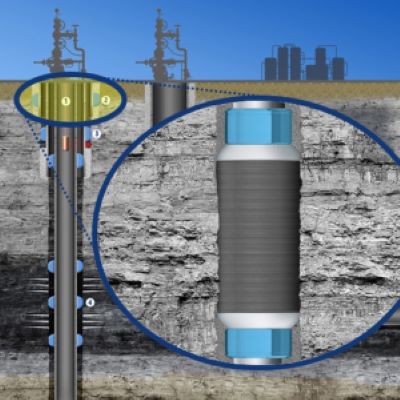

- Well Barriers Analysis and Technical Well Barriers

- Analysis of Well Barriers

- Concepts of Technical Well Barriers

- Description of Typical Barrier Elements

- Well Integrity Operations and Handling

- Pressure Monitoring Techniques

- Drilling Operations Management

- Optimization of Well Production

- Problems in Wells and Handling

- Corrosion Mitigation and Prevention

- Surface Casing Repairs

- Temporary Well Abandonment Procedures

- Casing Perforation Techniques

- Review of Primary Cementing and Well Integrity

- Downtime and Maintenance Cost Management

- Testing Seals on Wellheads

About the Course Leader

Prof. Herianto, Ir, M.Sc., Ph.D. is a distinguished professor with a Ph.D. in Petroleum Engineering. He has been a senior lecturer in the Petroleum Engineering program at UPN Veteran Yogyakarta since 1983 and has taught in various postgraduate programs. With over three years of experience as a Support Manager at GeoQues Schlumberger and consulting roles in multiple energy projects, he has contributed to national energy resilience initiatives and has been involved in numerous oil and gas projects.

Prof. Herianto has trained extensively in drilling certification and well control, delivering over 50 training topics for major companies such as Pertamina, Chevron, and Total Indonesia. He has also served as a resource person for the Ministry of Energy and Mineral Resources and has published research in the fields of oil and gas and geothermal energy. His expertise in Well Barriers and Well Integrity has made him a sought-after instructor in various oil companies and training programs across Indonesia.