- This event has passed.

Condition Based Maintenance

Background & About the Course

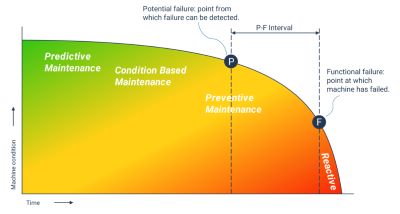

In modern industrial operations, Condition Based Management System (CBMS) has become an increasingly relevant approach to enhance the efficiency and effectiveness of asset management. CBMS utilizes real-time data from asset conditions to plan timely and appropriate maintenance actions. This allows organizations to reduce downtime, minimize unnecessary maintenance costs, and extend the overall lifespan of assets.

This training is designed to provide a comprehensive understanding of the implementation and analysis of CBMS across various industrial sectors. Participants will learn data collection techniques, asset condition analysis, and strategic data-driven decision-making. With a technology and data-driven approach, this training helps organizations adapt to the demands of Industry 4.0 and improve their business competitiveness.

Course Objectives

After completing this training, participants are expected to:

- Understand the concepts and benefits of Condition Based Management System (CBMS).

- Identify the steps for implementing CBMS within an organization.

- Conduct asset condition analysis using relevant techniques and software.

- Develop condition-based maintenance strategies to enhance operational efficiency.

- Reduce asset failure risks through data-driven decision-making.

Who Should Attend

This training is recommended for:

- Managers and supervisors in maintenance and operations.

- Engineers responsible for asset maintenance and analysis.

- Professionals in reliability engineering and asset management.

- Individuals involved in infrastructure management and maintenance strategy development.

Course Content

- Introduction to Condition Based Management System

- Overview of Condition Based Maintenance and Management System

- Key Principles and Benefits of CBMS

- Tools and Technologies for Condition Monitoring

- Case Study: Implementing CBMS in Industrial Settings

- Data Collection and Analysis

- Techniques for Collecting Real-Time Data from Assets

- Introduction to Predictive Maintenance Tools (e.g., Vibration Analysis, Thermal Imaging)

- Data Interpretation and Fault Diagnosis

- Workshop: Developing a Monitoring Framework for Assets

- Strategy Development and Implementation

- Building a CBMS Strategy: From Planning to Execution

- Risk Assessment and Decision-Making in CBMS

- Performance Metrics for Evaluating CBMS Success

- Final Presentation: Designing a CBMS Plan for Your Organization

About the Course Leader

Cecep Slamet Abadi, ST., MT is an associate instructor at FJM with a background in Mechanical Engineering for both undergraduate and graduate studies. He has been an active lecturer since 1996 and has experience in industry and consulting, including roles at LAPI ITB, Puslitbang Air, PINDAD, and conducting energy audits at Pertamina EP Pangkalan Susu, Tambung, and Rengasdengklok. He is also part of the competency testing team for IATKI (Indonesian Electrical Engineering Association).

In terms of industrial training, Mr. Cecep has conducted over 150 in-house and public training sessions for organizations such as Indonesia Power, PLTA Saguling, Freeport-Papua, Chevron Oil/Gas, Chevron Geothermal, Premier Oil, Pupuk Sriwijaya, Pupuk Kujang, Badak LNG, and many others.