Introduction

Mastering advanced techniques in Applied Reservoir Engineering is essential for unlocking the full potential of hydrocarbon reservoirs. By utilizing cutting-edge tools like reservoir simulation, enhanced well testing, and strategic field development planning, engineers can ensure sustainable and efficient recovery of oil and gas. If you’re ready to take your skills to the next level, this article will guide you through the advanced principles and methodologies shaping modern reservoir engineering.

Why Advanced Techniques Matter in Reservoir Engineering

Reservoirs are complex systems influenced by various physical, chemical, and geological factors. Basic approaches often fall short in addressing challenges such as heterogeneous reservoirs, fluctuating production rates, and unpredictable drive mechanisms. Advanced techniques enable:

- Accurate performance forecasting.

- Improved recovery efficiency.

- Sustainable field development strategies.

Whether you’re managing mature fields or unconventional reservoirs, mastering these techniques is vital for long-term success.

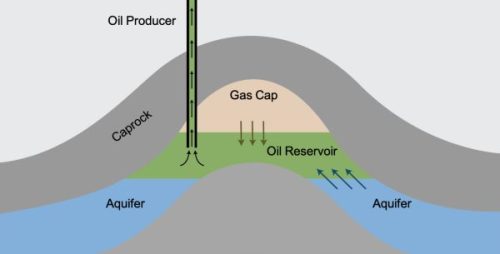

Reservoir Drive Mechanisms: The Engine of Recovery

Understanding and optimizing reservoir drive mechanisms is a cornerstone of advanced reservoir management. These mechanisms include:

- Gas Cap Expansion: Utilizes gas pressure to displace oil toward production wells.

- Water Drive: Sustains reservoir pressure through natural water influx.

- Gravity Drainage: Exploits gravity to mobilize hydrocarbons in sloping reservoirs.

- Compaction Drive: Leverages rock compaction for additional recovery.

Identifying the dominant mechanism helps engineers design targeted recovery strategies, improving efficiency and reducing waste.

Advanced Well Testing Techniques for Enhanced Analysis

Well testing remains one of the most effective methods for reservoir evaluation. Advanced techniques include:

1. Pressure Transient Analysis (PTA):

PTA reveals reservoir characteristics, including permeability, skin factor, and boundaries.

2. Type-Curve Matching:

By comparing production data to pre-defined models, engineers can predict reservoir behavior under various scenarios.

3. Multiphase Flow Testing:

This method provides insights into fluid interactions, including gas, oil, and water, enabling better production optimization.

These techniques not only provide critical data but also help in identifying potential operational challenges before they escalate.

The Role of Reservoir Simulation in Field Management

Reservoir simulation has revolutionized the way engineers approach field development. This predictive tool helps simulate fluid flow, forecast production, and evaluate recovery techniques.

Key Benefits of Reservoir Simulation:

- Enhanced Planning: Simulate multiple recovery scenarios to choose the most effective one.

- Risk Mitigation: Anticipate challenges and test solutions virtually.

- Optimized Recovery: Refine well placement and recovery techniques to maximize output.

By integrating dynamic and static models, engineers can better understand reservoir behavior and develop data-driven strategies.

Field Development Planning: Strategies for Success

Field development planning is essential for maximizing recovery while maintaining operational efficiency.

Advanced Strategies Include:

- Reservoir Characterization: Combining seismic data, core analysis, and well logs to create a comprehensive reservoir model.

- Enhanced Oil Recovery (EOR): Techniques such as gas injection and chemical flooding to boost recovery rates.

- Production Optimization: Designing production policies that balance short-term output with long-term sustainability.

Strategic planning ensures that every phase of development—from exploration to decommissioning—is optimized for success.

Immiscible Displacement and Fractional Flow Techniques

Immiscible displacement methods, such as water flooding, are key to maintaining reservoir pressure and improving sweep efficiency. Fractional flow analysis helps engineers predict breakthrough times and optimize recovery strategies.

Key Insights:

- Breakthrough Time Calculation: Determines when injected fluids reach production wells.

- Critical Rate Analysis: Identifies the optimal injection rate for maximum recovery.

These insights are particularly valuable for managing mature fields with declining pressure.

Horizontal Wells: A Game-Changer in Reservoir Development

Horizontal drilling has transformed reservoir development by offering significant advantages over traditional vertical wells.

Benefits Include:

- Increased Reservoir Contact: Accessing larger areas of the reservoir.

- Reduced Water and Gas Coning: Minimizing unwanted fluid production.

- Improved Sweep Efficiency: Enhancing recovery in low-permeability reservoirs.

Horizontal wells are especially effective in unconventional reservoirs, such as shale plays and naturally fractured systems.

Conclusion

Advanced techniques in Applied Reservoir Engineering provide the tools needed to tackle modern challenges in reservoir management. By leveraging simulation, enhanced well testing, and strategic field development planning, engineers can optimize production, extend reservoir life, and maximize recovery.

Are you ready to advance your skills in reservoir engineering? Contact us now via WhatsApp at 6282130176197 to learn more about training programs designed to empower engineers and geoscientists. Let’s take your expertise to the next level!