- This event has passed.

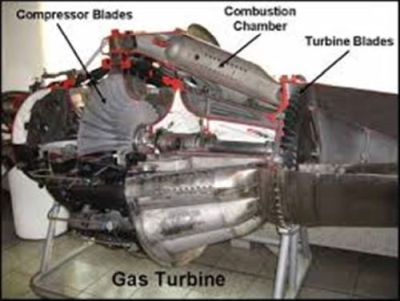

Gas Turbine and Compressor Operation and Maintenance

BACKGROUND:

Gas turbines and compressors are critical components in various industries, including power generation, oil and gas, and petrochemicals. Their efficient operation and maintenance are essential for ensuring reliability, optimizing performance, and minimizing downtime. This training program is designed to provide participants with a comprehensive understanding of gas turbine and compressor systems, including their principles of operation, common challenges, and best practices for maintenance. By enhancing technical knowledge and operational skills, this training aims to empower participants to achieve safe, efficient, and cost-effective management of these vital assets.

OBJECTIVES:

After the course participant:

- Have a good knowledge of gas turbine out and technology include thermodynamic concepts, construction, detail components and function

- Will improve their ability to understand cause and effect of failure to guide root cause analysis in problem solving and troubleshooting

- Familiar with product of gas turbine which is used in the gas plant

RECOMMENDED PARTICIPANTS:

- Maintenance Engineer/ Superintendent/ Supervisor

- Rotating Engineer/ Superintendent/Supervisor

- Power Plant Engineer/ Superintendent / Supervisor.

- Everybody who wants to add knowledge and interest in the above subject

COURSE OUTLINE:

- Overview of Gas Turbines

-

- History of gas turbine

- Gas turbine in oil and gas industry

- Brayton cycle

- Gas turbine art and design

- Engine design

- Operation principle

- Engine case and inlet air

- Gas turbine in detail assembly and function of components

-

- Compressor section

- Diffuser and Combustor

- Turbine and exhaust

- Auxiliary Components and Accessories: Bearings and Seals, Gears

- Gas turbine bearing and lubrication system

-

- Ignition system

- Bearing and seals

- Fuel gas and gas system

- Basic combustion in gas turbine

-

- Heating value in natural gas (LHV and HHV), Wobb number

- Stoichiometric combustion

- Emission of combustion

- How gas burned in combustion chamber

- Cooling technology and thermal barrier coating

- Compressor in gas turbine

-

- Energy conversion in compressor

- How compressor work (increase pressure & flowing gas)

-

- Gas flow compressor phenomena stall and surge,

- How to control surge (IGV and bleed valve)

- Compressor failure and material

- Turbine how it works

- Convert Pressure and temperature to Mechanical energy

- How blade turbine work

- Internal cooling and coating

- Failure in turbine component

- Gas turbine operation and control

-

- Operation gas turbine for gas compressor

- Operation gas turbine for Power Generation

- Fuel control system

- IGV control system

- Lubrication control system

ABOUT THE COURSE LEADERS:

Cecep Slamet Abadi, ST., M.T adalah salah satu associate instructor di FJM dengan latar belakang Pendidikan Teknik Mesin untuk jenjang S1 & S2.

Selain aktif sebagai dosen sejak tahun 1996, beliau juga memiliki pangalaman dalam bidang industry & konsultan di antaranya di LAPI ITB, Puslitbang Air, PINDAD, Audit Energi di Pertamina EP Pangkalan Susu, Tambung & Rengasdengklok, serta sebagai team uji kompetensi si IATKI (Ikatan Akhli Ketenagalistrikan Indonesia). Untuk industrial training, Pak Cecep telah mengajar lebih dari 150 in-house maupun public training di antaranya: Indonesia Power, PLTA Saguling, Freeport-Papua, Chevron Oil/Gas, Chevron Geothermal, Premier Oil, Pupuk Sriwijaya, Pupuk Kujang, Badak LNG, dan lain-lain.